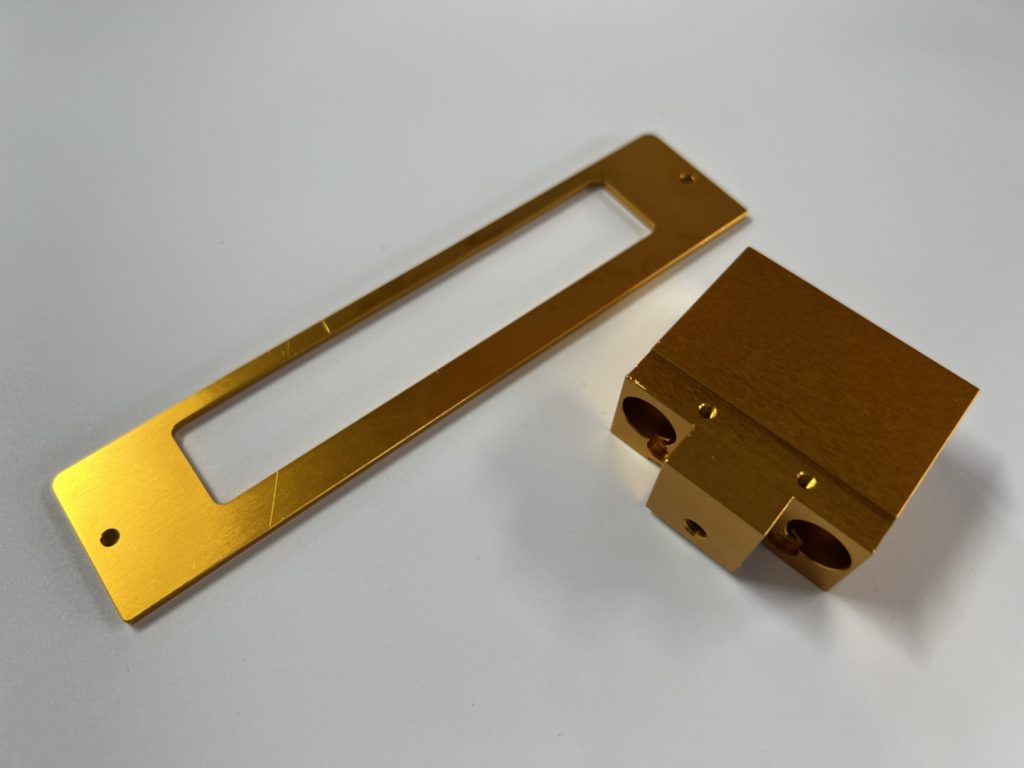

Types of Materials Available at PREPART for CNC Machining Parts

PREPART offers a wide selection of materials for its CNC machining parts. From metals like aluminum, brass, and stainless steel to plastics like acrylic, nylon, and polycarbonate, they have options that fit various needs and specifications. Each material comes with unique properties that can impact the performance of the final product, and their team of experts can help guide customers in making the best choice for their project. With the ability to produce parts in precise dimensions and tolerances, coupled with a diverse range of materials to choose from, PREPART provides an optimal solution for CNC machining needs.

a. Aluminum

Aluminum is a versatile metal that has become an essential part of modern civilization. Its unique properties – lightweight, corrosion resistance, electrical conductivity, and thermal conductivity – make it ideal for a wide range of applications, from transportation to construction to packaging. Aluminum is used in everything from beverage cans to aircraft and is recyclable, which makes it an eco-friendly choice. Moreover, aluminum is durable and long-lasting, requiring minimal maintenance and reducing replacement costs in the long run. In addition to its practical uses, aluminum is also valued for its aesthetic appeal, which has led to its use in building facades and architectural features. As a result, aluminum has become an indispensable material in our daily lives.

b. Steel

Steel – the backbone of modern civilization. This versatile material has been the driving force behind some of the greatest infrastructure projects in history, from towering skyscrapers and sprawling bridges to high-speed trains and aircraft. With its exceptional strength, durability, and flexibility, it is no wonder that steel has become the go-to material for many industries. Whether you’re building a new skyscraper, manufacturing a fleet of cars, or constructing a new power plant, steel is the backbone that underpins it all. With advances in technology and growing demand for sustainable materials, the future of steel looks as bright as ever. From microstructures to macroscopic properties, the world of steel is filled with endless possibilities.

c. Stainless Steel

Stainless steel is a wonder material that seems to be able to do it all. It’s strong, durable, and corrosion-resistant, making it the perfect choice for a wide range of applications. From kitchen appliances to surgical tools, stainless steel has become so ubiquitous in our lives that it’s easy to take for granted. But the truth is, this versatile material has changed the way we live and work in countless ways. Whether you’re cooking a meal or building a skyscraper, stainless steel is there to help you get the job done right. So next time you see a gleaming stainless steel surface, take a moment to appreciate all the amazing things this material can do.

d. Copper

Copper has a rich history of practical uses, from currency and jewelry to electrical wiring and plumbing. This reddish-brown metal has a distinct ability to conduct heat and electricity, making it an essential material in modern industries. Copper is also malleable, meaning it can be easily shaped and formed into intricate designs. This versatility has made copper an enduring material throughout the ages. In addition, copper is believed to have health benefits, leading many to wear copper bracelets or drink from copper cups. Whether it’s for aesthetics or functionality, copper is a valuable resource that continues to play a significant role in modern society.

Benefits of Using PREPART’s CNC Machining Services

PREPART’s CNC Machining Services provide numerous benefits for businesses and manufacturers. With high precision and accuracy, these services can produce complex components and parts with ease. This means that businesses can enjoy fast turnaround times and improved efficiency in manufacturing processes. Additionally, CNC Machining allows for greater material efficiency, reducing waste and saving costs. The sophisticated technology used in these services also ensures consistent quality and repeatability of parts, leading to fewer errors and defects. Overall, by utilizing PREPART’s CNC Machining Services, businesses can streamline their manufacturing processes, save costs, and produce high-quality parts at a faster rate.

a. Quality Assurance

Ensuring quality assurance is vital for any organization that wants to deliver reliable products or services to its customers. Simply put, quality assurance involves checking, monitoring, and testing every aspect of a product or service to make sure it meets or exceeds established standards. It can include everything from checking raw materials, and inspecting every stage of production, to running tests to ensure the end product or service works as intended. Quality assurance helps companies identify problems before they become significant issues, which can ultimately save time and money. A solid quality assurance program can also help organizations earn the trust and satisfaction of their customers, resulting in long-term loyalty. Therefore, investing in quality assurance is a wise move for any business that aims to provide the best possible outcome for its customers.

b. Flexibility and Versatility in Design

When it comes to design, one key aspect that can make all the difference is flexibility and versatility. These traits allow designers to adapt to changing circumstances and create more effective solutions. Being able to pivot and shift gears quickly is often essential in the design process, as unexpected challenges can arise that require a different approach. Moreover, flexibility can also help designers create more appealing and user-friendly designs, as they are better able to accommodate the needs and preferences of diverse audiences. Overall, the importance of flexibility and versatility in design cannot be overstated, and it is something that all designers should strive to prioritize in their work.

c. Cost-Effective Solutions for Parts Production

When it comes to parts production, cost-effectiveness is always a top priority. Companies need to optimize their processes to produce parts efficiently without sacrificing quality. Luckily, there are now many innovative solutions available that can help businesses achieve this balance. Some of these include using additive manufacturing technologies, implementing automated processes, and using more affordable materials. By taking advantage of these cost-effective solutions, companies can gain a competitive edge while also reducing their expenses. Plus, they can rest assured that they are doing their part in advancing the field of manufacturing and making it more sustainable for future generations.

Tips to Ensure High-Quality Parts with PREPART’s CNC Machining Processes

Are you tired of experiencing low-quality parts in your CNC machining processes? Look no further than PREPART for expert tips to ensure your parts meet the highest standards. Their team of experienced professionals knows the ins and outs of CNC machining, and they are equipped with the latest technology to take on any project. To achieve high-quality parts, PREPART emphasizes the importance of starting with high-quality materials and proper tooling. They also stress the significance of carefully calibrating machines, using the right software and tool paths, and closely monitoring the manufacturing process. With PREPART, you can trust that your parts will be manufactured with precision and consistency, ensuring your overall project’s success.

a. Understand the machinability of different materials

When it comes to machining materials, not all materials are created equal. Understanding the machinability of different materials is crucial when it comes to successfully crafting a product. Some materials may be more difficult to work with due to their composition, while others might require specific techniques and tools to prevent damage. It’s important to evaluate the specific qualities of each material to determine the best approach to machining it. By taking the time to understand the machinability of different materials, machinists can create high-quality parts that meet the exact specifications of their clients.

b. Select the right cutting tools and speeds

When it comes to cutting materials, selecting the right cutting tools and speeds is crucial. Using the wrong tool or speed can not only damage the material but also lead to injuries. It’s important to consider factors such as the material’s thickness, hardness, and texture when selecting the appropriate tool. Similarly, the cutting speed should be adjusted to ensure a clean cut without putting too much pressure on the material or the tool itself. With the right tools and speeds, you can achieve precise and efficient cuts, making your projects more successful and safe.

c. Consider other factors such as surface finish, tolerances, etc.

When it comes to manufacturing, there’s more to consider than just the design of a product. Other factors such as surface finish and tolerances can make a big difference in the final outcome. Surface finish refers to the texture or smoothness of a surface, which can affect not only the appearance but also how well the product functions. Tolerances, on the other hand, refer to the allowable variation in dimensions. It’s important to consider these factors to ensure the product matches the desired specifications. By taking into account all of these aspects, manufacturers can create high-quality products that meet the needs and expectations of their customers.

Common Applications of PREPART’s CNC Machined Parts

When it comes to manufacturing parts and components, precision is key. That’s where PREPART’s CNC machined parts come in. By using computer numerical control (CNC) technology, PREPART produces parts with accuracy and consistency that simply cannot be achieved with manual machining. These parts have a wide range of applications, from aerospace and automotive to medical devices and consumer electronics. Whether you need complex shapes, intricate details, or simply high-quality custom parts, PREPART’s CNC machining capabilities can deliver. So why settle for anything less than precision excellence? Choose PREPART for all your CNC machined part needs.

a. Automotive Components

Automotive components are integral parts of any vehicle, playing a crucial role in its performance and overall functionality. From the engine and transmission systems to the brakes and steering, every component is carefully crafted and engineered to work together seamlessly. While some components may not be as visible as others, their importance cannot be overstated. For example, the battery and alternator are often overlooked, but without them, the car wouldn’t even start! Similarly, air filters help to keep the engine running smoothly, and shock absorbers ensure a comfortable ride even on bumpy roads. With advancements in technology, automotive components are becoming increasingly complex and specialized, leading to improved efficiency and safety in our vehicles.

b. Aerospace Parts

Aerospace parts serve as the backbone of the aviation industry and lay the foundation for the optimal performance of aircraft. These precision-engineered parts go through rigorous testing before being implemented into aircraft, ensuring that each component meets the standards required for flight. From the smallest screws to complex control systems, aerospace parts are critical to the safe and efficient operation of aircraft. Given the complex nature of aviation, the reliability and quality of each component are essential to guarantee passenger safety. The continuous advancement of aerospace technology has led to the development of innovative materials and techniques, creating a new wave of aerospace parts built for efficiency and longevity. As the aviation industry continues to evolve, the role of aerospace parts remains a crucial aspect of the industry’s future success.

c. Medical Devices

Medical devices have completely revolutionized the healthcare industry, allowing for increased accuracy, efficiency, and patient safety. From surgical equipment to diagnostic tools, these innovative devices have become integral in the delivery of medical care. With advancements in technology, medical devices have become smaller, more effective, and more user-friendly. They allow for real-time monitoring of patient health and can be used for a variety of purposes such as drug delivery, critical care monitoring, and emergency response. As the demand for healthcare services continues to increase, medical devices will continue to play a critical role in saving lives and improving patient outcomes.

In conclusion, PREPART can provide CNC machining services for many different materials to create parts with high quality and precision. With its vast selection of different materials, PREPART has the capability to create parts specific to its customer’s exact needs and requirements. Customers have used PREPART’s CNC machined parts in many fields such as automotive components, aerospace parts, medical devices, and more. It is essential that users understand the machinability of each material, and select the appropriate cutting tools and speeds for optimal results when using PREPART’s CNC machining services. In addition, other factors such as tolerances and surface finish should be taken into consideration when optimizing the process for maximum efficiency. Overall, PREPART offers a range of reliable solutions for customers looking for cost-effective production of custom parts with versatility in design and quality assurance guaranteed. each so that you can select the one that is most suitable for your project needs. Each process will provide an additional layer of protection to your finished parts and will help ensure that they stay looking good and performing well for many years to come. Be sure to take the extra time to consider your surface finishing options before making a final decision on what would best suit your uniquely specific needs.