CNC Milling

CNC Milling

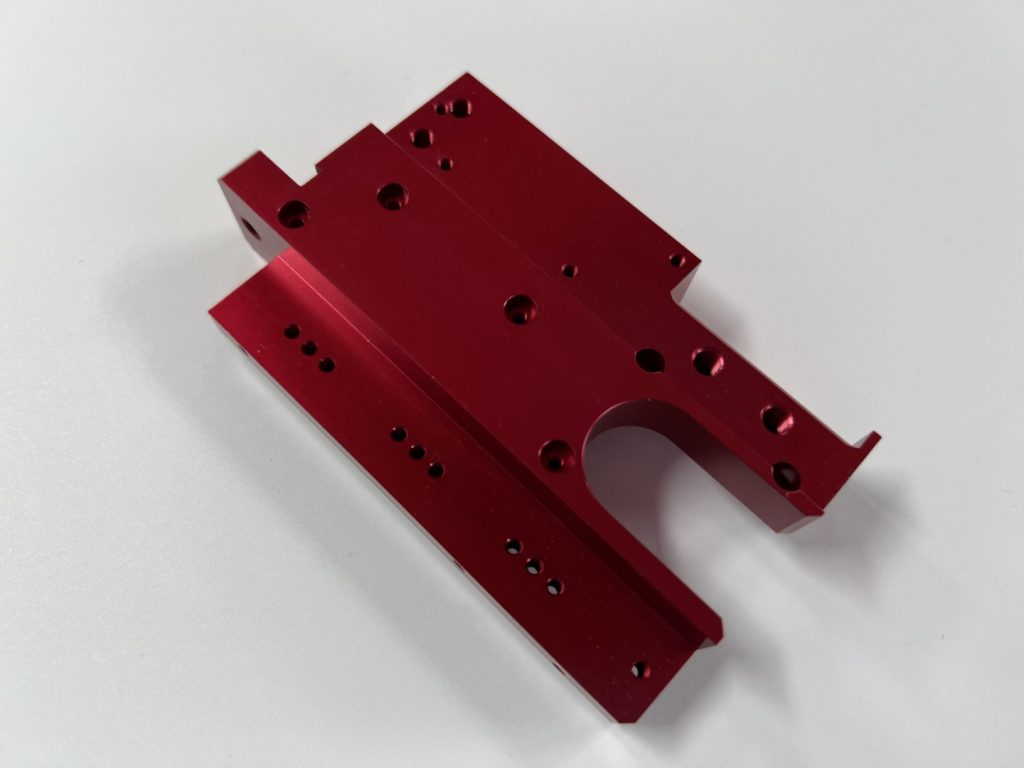

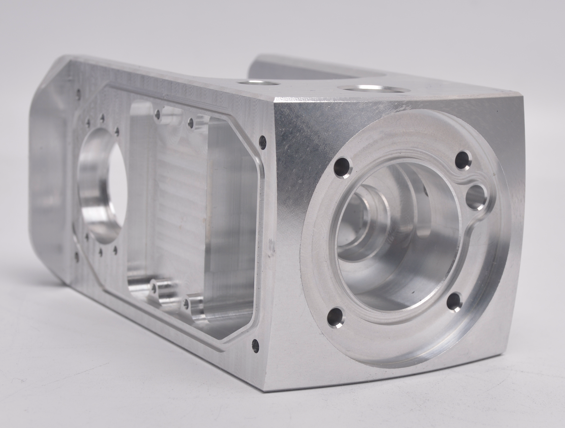

PREPART is ready to provide CNC milling services for a range of applications and materials.

Our CNC milling machines can work with most commercial materials, including aluminum, steel, brass, plastics, and polymers with tight tolerances.

Looking for a reliable, quick-turn manufacturer of machined plastic and metal parts? With 20+ of CNC machines, our in-house capacity ensures your parts are shipped on-time, every single time.

At PREPART, our machining facilities are designed for both rapid prototyping and low-volume production of end-use components.

CNC milling materials options

- ABS

- Acrylic

- POM

- Nylon

- Teflon

- PVC

- Polystyrene

- Ultem

- Polyethylene

- Lexan/Polycarbonate

- PEEK

- PTFE

- Aluminum 6082

- SS 316

- C45

- Aluminum 6061

- SS 303

- Q235

- Aluminum 7075

- SS 304

- A2 Steel

- Aluminum 5083

- SS 301

- S355J2

- Aluminium 6060

- E-Cu57

- S235JR

- Aluminium 2017A

- CuZn39Pb3

- 42CrMo4

- MIC Aluminum

- Ti-6Al-4V

- 16MnCr5

CNC Milling Tolerance at Prepart

| Metals With Drawing | Plastics With Drawing | No Drawing | |

| Linear Dimension | +/- 0.01 mm | +/- 0.05 mm | ISO 2768 Medium |

| +/- 0.0003 inch | +/- 0.002 inch | ||

| Hole Diameters | +/- 0.008 mm | +/- 0.05 mm | ISO 2768 Medium |

| (Not Reamed) | +/- 0.0003 inch | +/- 0.002 inch | |

| Shaft Diameters | +/- 0.004 mm | +/- 0.05 mm | ISO 2768 Medium |

| +/- 0.00016 inch | +/- 0.002 inch |

CNC Milling Parts Surface Treatment Options at Prepart

| Anodizing Type III | Polishing |

| Anodizing Type III | Black Oxide |

| Chromate Plating | QPQ |

| As Machined | Zinc Plating |

| Bead Blasted | Nickel Plating |

| Heat treatment | Powder Coating |

| Thread Inserts | Laser Engraving |

Why Chosse prepart with cnc milling service

Flexible mfg

quick quote

From 1 pcs

Good QUALITY

COST EFFECTIVE

best SERVICES

DFM report

SATISFACTION

Case Applications Of CNC Milling

Here are ten application cases where CNC milling parts are commonly used:

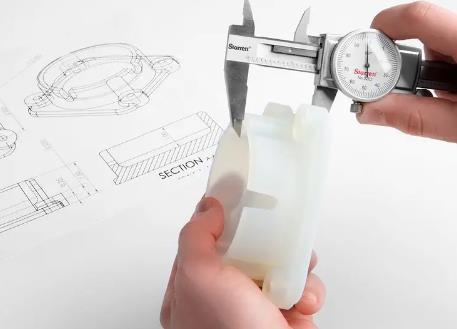

Prototyping and Product Development: CNC milling is often used in the early stages of product development to create prototypes and test designs before mass production.

Aerospace Components: CNC milling is crucial for producing complex aerospace components such as aircraft structural parts, engine housings, and wing components.

Automotive Tooling: CNC milling is used to create molds, dies, and tooling for automotive manufacturing processes, including stamping and injection molding.

Medical Devices: CNC milling is employed to manufacture intricate and precise medical device components, such as surgical instruments, implants, and diagnostic equipment.

Electronics Enclosures: CNC milling is used to create precise enclosures and housings for electronic devices, ensuring proper fit and protection.

Custom Jewelry: CNC milling is utilized in crafting intricate and customized jewelry pieces, including rings, pendants, and earrings.

Industrial Machinery Components: CNC milling is crucial for producing components for various industrial machinery, such as gears, shafts, and structural parts.

Consumer Products: CNC milling is employed in creating consumer goods like smartphone cases, laptop housings, and kitchen appliances.

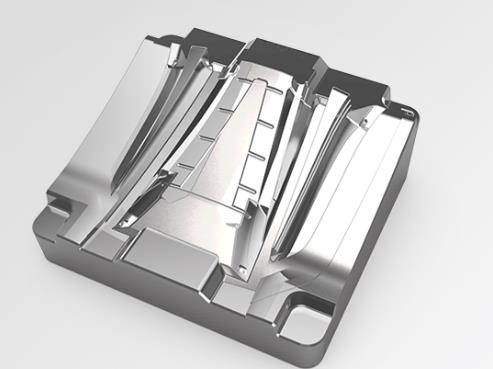

Die and Mold Making: CNC milling is used to create dies and molds for manufacturing processes such as injection molding and die casting.

Architectural Components: CNC milling is utilized in crafting architectural elements such as decorative panels, moldings, and intricate facades.

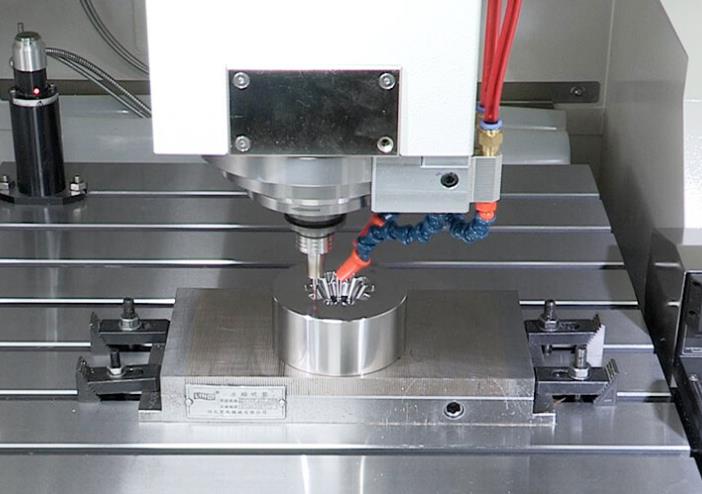

CNC Milling Machining Equipment at Prepart

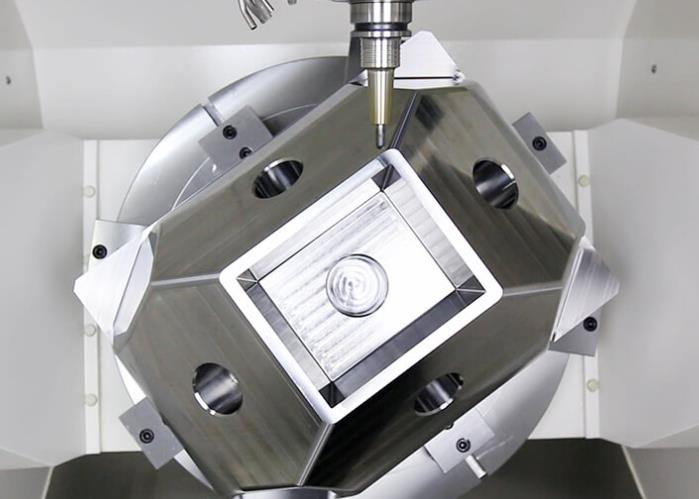

5 AXIS CNC MACHINING CENTER JDMR600 * 3 sets

- X/Y/Z Travel:650/660/500mm

- A/C Rotation Range:-120°~90°/360°

- Worktable Size:Ф630mm

- Workload:400kg

5-Axis High-Speed Machining Center for Heavy Precision Mold Parts Processing and Die Casting Parts Drilling, Milling, Boring and Grinding.

5 AXIS CNC MACHINING CENTER JDR300 * 3 sets

- X/Y/Z Travel:390/510/300 mm

- A/C Rotation Range:-110°~90°/ 360°

- Worktable Size:Ф300mm

- Max. Load:100kg

Machining Center for Mirror Machining is Applicable to the Processing of Mirror Mold Parts with High Surface Quality and High Precision Requirements in 3C Consumer Products, Medical Treatment, Optics, Automotive Electronics and Other Industries.

JDHGT 800T 3AXIS CNC MACHINING CENTER *15 sets

- X/Y/Z Travel:800/800/350mm

- X/Y/Z Travel:800/800/450mm

- Worktable Size:850×850mm

- Max. Load:1000kg

3-Axis High-Speed Machining Center, Suitable for Precision Milling of Mold Parts, Micro Hole Drilling of Metal and Special Materials and Precision Hole Grinding, it can stably realize 5-20μm machining accuracy.

JDHGT 1200T 3 AXIS CNC MACHINING CENTER*3 sets

- X/Y/Z Travel:1200/800/350mm

- X/Y/Z Travel:1200/800/450mm

- Worktable Size:1250×850mm

- Max. Load:1000kg

3-Axis High-Speed Machining Center, Suitable for Milling Medium and Large Precision Mold Parts, Micro-Hole Drilling of Metal and Special Materials and Precision Hole Grinding, 5-20μm machining accuracy can be stably achieved

What's 3 Axis CNC Milling? Is it Fit For Your Parts Producing?

3-axis CNC milling refers to a machining process where a computer-controlled milling machine operates along three axes: X, Y, and Z. This means that the cutting tool can move horizontally (along the X and Y axes) and vertically (along the Z axis) to shape and remove material from a workpiece. It’s one of the most common and basic forms of CNC milling.

In a 3-axis CNC milling setup, the workpiece remains stationary while the cutting tool moves to create shapes, holes, slots, and other features. This process is suitable for producing a wide range of parts, including relatively simple and moderately complex geometries. However, it has limitations in terms of creating highly intricate and complex designs, as well as parts that require undercuts or multiple angles of machining.

3-axis CNC milling is a versatile and cost-effective method suitable for many applications, including:

Prototyping: Creating prototypes and initial designs for testing and evaluation.

Simple Components: Manufacturing parts with basic shapes, holes, and surfaces.

Machining Flat Surfaces: Producing parts with flat and slightly contoured surfaces.

Engraving: Adding text, logos, and designs onto surfaces.

Drilling and Tapping: Creating holes and threads in various materials.

Rapid Production: Generating parts with moderate complexity at a relatively fast rate.

However, for parts with more complex geometries, tighter tolerances, intricate features, or undercuts, 3-axis CNC milling may have limitations. In such cases, advanced machining techniques like 4-axis or 5-axis CNC milling might be more suitable.

When deciding whether 3-axis CNC milling is a good fit for your parts production, consider factors like the complexity of your design, required tolerances, production volume, and the capabilities of your CNC milling service provider. If your parts meet the criteria for 3-axis milling, it can be a cost-effective and efficient method for manufacturing a wide range of components.

What's 5 Axis CNC Milling? Is it Fit For Your Parts Producing?

5-axis CNC machining is an advanced manufacturing process that involves the use of a computer-controlled milling machine with the capability to move along five different axes simultaneously. These axes are typically labeled as X, Y, Z, as well as two rotational axes often referred to as A and B. This multi-axis movement allows for highly complex and intricate machining operations, making it suitable for producing parts with intricate geometries, contours, undercuts, and multiple angles.

In 5-axis CNC machining, the cutting tool can tilt and swivel to reach different angles and orientations, providing greater flexibility and precision. This capability enables the machine to access hard-to-reach areas and perform more complex operations in a single setup, reducing the need for multiple tool changes and setups. As a result, 5-axis machining can significantly improve efficiency, reduce cycle times, and enhance the accuracy of the final parts.

5-axis CNC machining is well-suited for producing parts with the following characteristics:

1. Complex Geometries: Parts with intricate shapes, curves, and contours that would be difficult or impossible to achieve with traditional 3-axis machining.

2. Undercuts: Parts that feature undercuts or features that require machining from multiple angles.

3. Multi-Axis Machining: Components that require machining on multiple sides or faces without repositioning the part.

4. High Precision: Parts with tight tolerances and demanding precision requirements.

5. Reduced Setups: Parts that benefit from reduced setup times and fewer tool changes.

6. Efficiency: High-efficiency production of complex parts with minimal manual intervention.

Common industries that benefit from 5-axis CNC machining include aerospace, automotive, medical, tool and die manufacturing, and any other sector that requires intricate and complex parts.

While 5-axis CNC machining offers many advantages, it’s important to note that it may be more costly compared to 3-axis machining due to the complexity of the machines and programming involved. Therefore, when considering whether 5-axis CNC machining is a good fit for your parts production, evaluate factors such as part complexity, required tolerances, production volume, and budget. If your parts require intricate features and complex geometries, 5-axis machining can provide exceptional results.

Advantages of CNC Milling Machining Services at Prepart

Precision and Accuracy: CNC milling provides exceptional accuracy and tight tolerances, ensuring consistent and precise results across multiple parts. This is crucial for industries requiring high-quality components.

Complex Geometries: CNC milling can create intricate and complex shapes, contours, and features that may be challenging or impossible with manual machining methods.

Versatility: CNC milling machines can work with a wide range of materials, including metals, plastics, composites, and more, allowing for flexibility in material selection.

Repeatability: Once a CNC program is developed, it can be used repeatedly to produce identical parts with consistent quality, reducing variability and ensuring uniformity.

Efficiency and Speed: CNC milling offers faster production rates compared to manual machining, as multiple operations can be automated and performed simultaneously.

Reduced Human Error: Automation minimizes the potential for human errors that can occur in manual machining, leading to improved part quality and reliability.

Cost-Effective for Medium to High Volumes: CNC milling becomes more cost-effective for larger production volumes due to reduced labor costs and increased efficiency.

Multiple Axis Machining: Multi-axis CNC milling (such as 3-axis, 4-axis, or 5-axis) allows for complex machining operations, undercuts, and angles, reducing the need for multiple setups.

Prototyping and Customization: CNC milling is well-suited for rapid prototyping and customization, allowing for quick iteration and adjustments in design.

Consistency Across Batches: CNC milling ensures consistent results across batches of parts, minimizing variability and ensuring that components fit and function as intended.

Reduced Lead Times: CNC milling can significantly reduce lead times compared to traditional manual machining methods, speeding up the overall production process.

CAD/CAM Integration: CNC milling can be seamlessly integrated with computer-aided design (CAD) and computer-aided manufacturing (CAM) software for efficient programming and machining.

Wide Range of Applications: CNC milling is used in various industries, including aerospace, automotive, electronics, medical, consumer goods, and more, highlighting its broad applicability.

Some Design Tips to Help You Create CNC Milling-friendly Parts:

Material Selection: Choose materials that are suitable for CNC milling and match your project’s requirements. Consider factors such as machinability, hardness, and thermal expansion.

Part Symmetry: Design parts with symmetry whenever possible. Symmetrical features simplify machining and help maintain balance during cutting.

Avoid Small Features: Minimize small, delicate features that could break during machining. If necessary, choose a larger tool size to ensure stability.

Radius and Fillets: Incorporate rounded internal and external corners with appropriate radii. Sharp corners can be challenging to machine and may lead to stress concentrations.

Undercuts and Overhangs: Limit undercuts and overhangs to avoid tool interference. Use support structures or consider 5-axis machining if complex geometries are necessary.

Tolerances: Specify appropriate tolerances for your design. Overly tight tolerances may increase costs and production time.

Feature Depth: If possible, design features with uniform depths to simplify tool selection and reduce tool changes.

Surface Finishes: Specify desired surface finishes to ensure your design’s aesthetics and functional requirements are met.

Part Orientation: Consider how the part will be fixtured and machined on the CNC milling machine. Minimize the need for multiple setups and repositioning.

Avoid Over-Complication: While CNC milling is versatile, overly complex designs can increase machining time and costs. Strive for a balance between functionality and simplicity.

Chamfers and Deburring: Add chamfers to edges to facilitate tool entry and exit, and to prevent sharp edges that may require post-machining deburring.

Tool Access: Ensure that tools can reach all required features without interference. Evaluate tool lengths, diameters, and angles.

Avoid Thin Walls: Thin walls can be prone to vibrations and deflection during machining. Opt for thicker walls to improve stability.

Consult with Machinists: Collaborate with CNC machining experts early in the design process. They can provide valuable insights and suggest design modifications to optimize manufacturability.

Test Prototypes: Create prototypes to test your design before full production. This can help identify and address any potential machining challenges or design issues.

Experience of Cooperating with Prepart – The Perfect CNC Milling Service

CNC milling is a crucial technique in modern manufacturing and provides sustainable solutions for different industries. From aerospace engineering to medical devices, CNC milling gives precise and top-quality results. However, finding the top-notch CNC milling service that aligns with your project objectives and delivers ultimate results can be a challenging task. Luckily, I have found an exceptional service provider, Prepart. In this blog, I will share with you my experience of cooperating with Prepart and how their CNC milling service has helped me achieve my project goals and objectives.

1. Quality Services: One of the key things I always consider in CNC milling is quality. With Prepart, I was not disappointed. They have some of the best machines in the industry and experienced engineers who can handle even the most complex projects with ease. Their CNC milling services come with excellent accuracy and repeatability, delivering outstanding results that meet my project requirements. Prepart’s high-quality services have always given me peace of mind as I know my project is in the right hands.

2. Cost-Effective Solutions: Another factor that I like about Prepart is their affordable prices. They offer highly competitive pricing without compromising on the quality of their CNC milling services. With Prepart, I get cost-effective solutions that help me keep within my budget while achieving my project goals. This has helped me save time and money while getting exceptional results.

3. Excellent Customer Service: Prepart has an amazing customer service team who are always willing to help and provide expert advice. Their team of experts walks me through the entire CNC milling process, giving detailed updates on the project’s progress. They are also very responsive and prompt in addressing any queries or concerns that I may have. This level of customer service keeps me coming back to Prepart for all my CNC milling needs.

4. Timely Delivery: At times, there are situations where quick turnaround is critical to meet project deadlines. Prepart understands this and always delivers on time – even when timelines are tight. Prepart’s team works fast and efficiently to ensure that they deliver quality results within the agreed timeline. This has always been a big plus for me as I don’t have to worry about delays or rescheduling.

5. Versatile Solutions: Prepart has a wide range of CNC milling services that cater to different industries and project requirements. From prototyping to production, Prepart has the right solution to handle any project. This flexibility makes it easy to work with them, knowing that I can always count on them to deliver.

Prepart is an exceptional CNC milling service provider that has helped me achieve my project goals and objectives. Their quality services, affordable pricing, excellent customer service, timely delivery, and versatile solutions have made them my go-to service provider for CNC milling. If you’re looking for a reliable and trustworthy CNC milling service provider, then Prepart should be your first choice. I highly recommend them to anyone who wants precise and reliable results and unmatched customer service.